In recent years, driven by both market conditions and national policies, China’s smart manufacturing sector has grown at an unprecedented pace, reaching an industrial output value of nearly 1.5 trillion RMB.

As the global economic environment becomes increasingly complex and major economies face downward pressure, countries around the world are placing greater emphasis on strengthening their manufacturing capabilities. Some even describe the situation as: “Whoever leads in manufacturing will lead the world.” This has accelerated technological innovation, pushed industrial transformation, and elevated smart manufacturing to the core of international competition.

Today, intelligent, green, and highly efficient production has become the mainstream direction for manufacturing development. More importantly, smart manufacturing is rapidly shaping into a global battleground among leading nations.

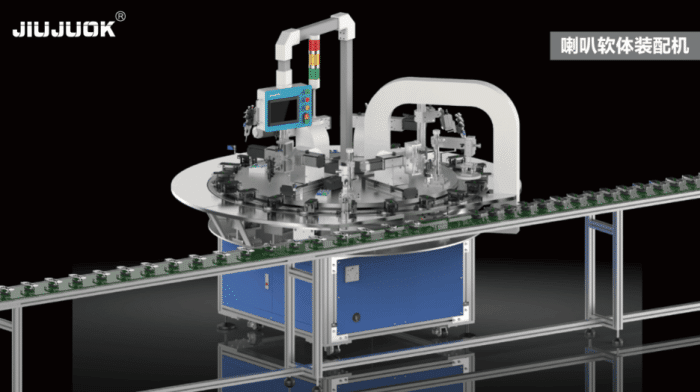

Automation in China’s Speaker Manufacturing Industry: Still Far From Expectations

Despite the national momentum, many Chinese electroacoustic speaker manufacturers have not kept pace. The level of automation—let alone full digital intelligence remains significantly lower than expected.

Even the most fundamental step toward intelligent manufacturing automation of production processeshas not yet been widely adopted across the industry. Historically, speaker manufacturing has been a laborintensive segment of China’s industrial chain. During the transitional period between the old and new economic eras, China’s abundant and low-cost labor force supported rapid industrial expansion. It also created an environment where automation remained in a longterm “dormant” or delayed state, as c-ompanies relied heavily on manual operations instead of upgrading their production equipment.

According to our research and understanding, the current situation is as follows: Many small and medium-sized enterprises in electro-acoustic speaker production pursue a low-investment, high-output model, with most companies unwilling to invest heavily in mechanical automation equipment. However, with ongoing socioeconomic development, the majority of these enterprises are now facing practical challenges such as "labor shortages, an age-structural shortage of workers, and soaring labor costs.

According to our research and understanding, the current situation is as follows: Many small and medium-sized enterprises in electro-acoustic speaker production pursue a low-investment, high-output model, with most companies unwilling to invest heavily in mechanical automation equipment. However, with ongoing socioeconomic development, the majority of these enterprises are now facing practical challenges such as "labor shortages, an age-structural shortage of workers, and soaring labor costs.

It must be said that as labor costs surge at an alarming rate, an increasing number of manufacturers are demanding higher levels and better quality of automation in equipment. This, in turn, "forces" equipment suppliers to develop products with greater automation to meet the industry's need to resolve labor conflicts and reduce labor costs by enhancing automation.

However, it is undeniable that China's manufacturing sector still largely relies on labor-intensive, low-end production with relatively low value-added. Most companies remain at the bottom of the "smile curve,"with per capita manufacturing output lagging behind developed countries. In the long run, an aging population will inevitably drive up labor costs, thereby eroding the cost-competitiveness advantage of Chinese manufacturing. Yet, even under such challenging circumstances, many speaker manufacturers show limited enthusiasm for adopting automated production. Why is this the case?

"The substantial upfront investment in automation equipment imposes short-term financial pressure on manufacturers, while traditional manufacturing sectors universally face difficulties in securing financing and high financing costs. This creates resistance to the widespread adoption of automation equipment," reflects the genuine concern of many decision-makers. Moreover, the operational costs of machinery are not low. Beyond procurement expenses, daily operational costs are exceptionally high. Machinery has a limited lifespan, requiring regular maintenance and replacement of wear-prone parts. For some sophisticated equipment, ongoing operational costs may even exceed the initial purchase price, posing a significant barrier to upgrading towards automated production.

Indeed, as many have noted, the high initial investment in automation equipment, coupled with low product standardization, makes it challenging to leverage economies of scale. This results in prolonged periods for equipment investments to yield returns. These factors present substantial challenges to implementing automated production. Simultaneously, some manufacturers believe that even with automation, it still struggles to fully replace human labor. Acquiring equipment additionally imposes financial burdens on business operations.

Some products involve complex processes that are difficult to fully automate. Certain specialized components still require manual assembly. This explains why automated manufacturing has not completely replaced human labor over the years.

As widely recognized, a prerequisite for speaker manufacturers to adopt automated production is high product standardization. However, overly standardized products yield low profit margins and struggle to gain recognition from high-end customers. This leads companies to pursue product differentiation to build competitive advantages, yet differentiation inherently limits scalability - creating a fundamental contradiction with automated production. Furthermore, while the efficiency of automated manufacturing is acknowledged, the cost of errors in automated systems far exceeds that of manual processes. If mistakes in automated production lead to losses substantially exceeding labor costs, this undoubtedly increases operational burdens and expenses for enterprises.